Our Strengths

Firm Integrity, Foundation of Trust

We believe integrity is the cornerstone of long-term business success. Whether it’s product labeling, technical commitments, or delivery timelines, we adhere to the principles of honesty and transparency to provide accurate and reliable information and services. Every collaboration is built on trust and is worth repeating.

Superior Quality, Never Compromised

Every PAOLUBE product is made with high-grade base oils and professional additives. Coupled with stringent process control and quality inspections, we ensure consistent excellence. Delivering outstanding performance is our basic promise to customers and a standard we uphold. From metal processing to high-temperature operations, we provide tailored solutions.

Expertise in Problem Solving

We understand the diverse challenges of different industries and production lines. PAOLUBE has a team of lubricant engineering experts familiar with various machine and process demands. They can quickly diagnose and resolve issues with precision. Whether it’s foaming, tool wear, oil mist, or sticky residue, we have extensive experience in solving lubrication-related problems.

Passionate Service, Start to Finish

We don’t just sell oil — we strive to be a part of our customer’s processing success. From technical consultation and on-site testing to follow-up evaluation, PAOLUBE offers proactive and timely service that helps enhance productivity and reduce costs. Our service isn’t just fast — it’s attentive, detailed, and warm.

Industry and Application

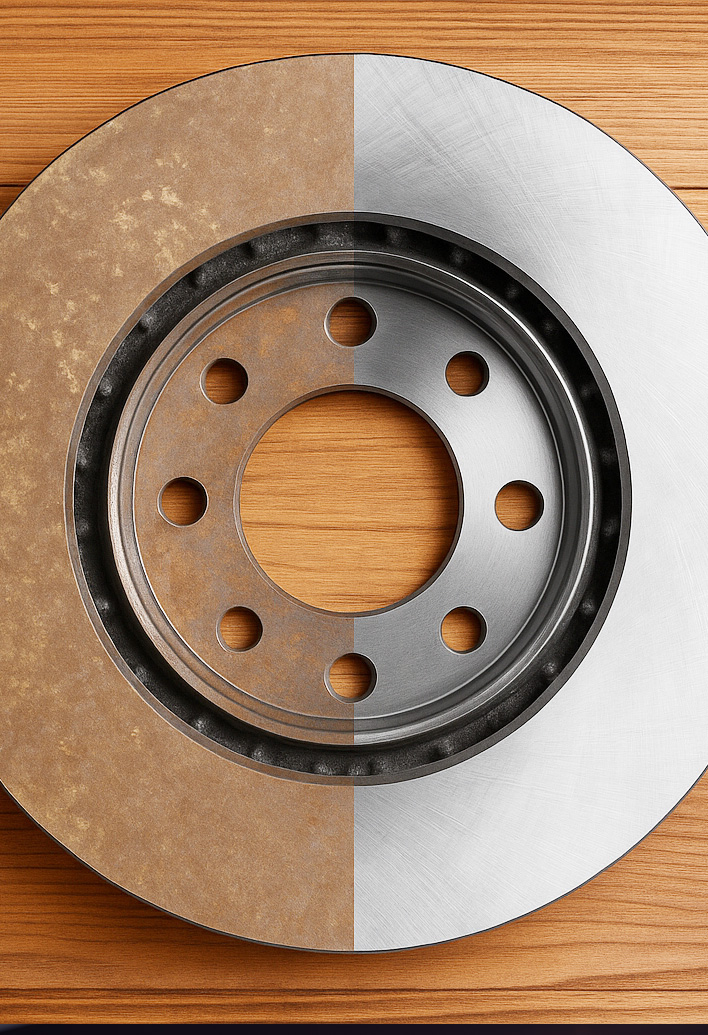

Automotive and Motorcycle Parts Machining

This industry faces the dual challenges of machining high-strength materials at high speeds, demanding lubrication solutions that are both highly stable and compatible with multiple materials to ensure efficient and long-lasting cutting performance.

- Stable cutting for hard materials

- Precise dimensions and roundness

- Longer tool life, fewer replacements

- Efficient cooling, less thermal distortion

- Smooth chip flow, no built-up edge

- Works with aluminum, cast iron, stainless steel

- Low-odor, antibacterial, user-friendly lubricants

Golf Club Head Machining

The extremely high demands for tool protection and cleanliness in golf club head manufacturing have driven us to develop specialized formulations with strong extreme pressure performance, clean residue-free properties, and excellent tool life extension — enabling high-precision, high-quality complex surface machining.

- Smooth machining of high-strength titanium and stainless steel

- Uniform surface finish with no ripples or tool marks

- Chip-free tools with preserved cutting-edge integrity

- Stable cooling to prevent overheating

- No oil stains, enhancing polishing efficiency

- Easy cleaning with no impact on subsequent coating

- High-end finish with no discoloration after machining

Hand Tool Machining

In the harsh environment where high-hardness steel processing and heat treatment are closely linked, PAOLUBE employs a specialized formula that balances anti-wear and anti-rust properties to ensure stable tool forming, consistent cutting performance, and superior surface quality.

- Ensures stable machining of high-hardness steel materials

- Provides excellent wear protection for molds and tools

- Maintains high cleanliness of the workpiece throughout processing

- Enhances forming precision for post-processing operations

- Offers short-term rust protection after machining to prevent oxidation

汽機車零件加工

The industry is facing the dual challenges of high-strength materials and high-speed machining, requiring us to develop lubrication formulas that are highly stable and can adapt to multiple materials to achieve efficient and long-lasting

cutting performance. Stable cutting performance of

- high-hardness materials

- , dimensional accuracy and roundness control

- , tool life and tool change cycle extension

- .Good efficiency, reduce thermal deformation,

- smooth chip removal, avoid chip accumulation

- , suitable for aluminum alloy, cast iron, stainless steel and other multi-material

- oils, stable antibacterial, low odor, friendly on-site

高爾夫球頭加工

The extremely high requirements of golf head machining for tool protection and cleanliness have prompted us to develop a professional formula with strong extreme pressure performance, clean and residue-free, and effectively extend tool life to achieve high-precision, high-quality machining of complex curved

- surfaces. Smooth machining surfaces of high-strength titanium and stainless

- steelConsistency, no ripples, no knife marks

- , no chip accumulation of the tool, maintaining the integrity of the tip

- , stable cooling control, no heat

- and no oil residue during processing, improving polishing efficiency

- and easy cleaning, does not affect

- the high texture and no color changes after the coating is processed.

手工具加工

In the harsh environment where high-hard steel processing and heat treatment are connected, PAOLUBE adopts a formula that takes into account anti-wear and anti-rust to achieve tool forming, cutting stability and surface quality

.

- The processing stability of high-hard steel materials

- , the anti-wear protection of molds and tools

- , the cleanliness of the workpiece is good, and it is easy to post-process

- . The tool has stable forming accuracy

- and short-term anti-rust protection after processing to avoid oxidation.

Purchase suitable products according to suitable needs

Services we provide

PAOLUBE focuses on the research and development and manufacture of high-performance metal CUTTING FLUIDS and industrial lubrication products, and is committed to providing customers with stable, SAFE and environmentally FRIENDLY SOLUTIONS. We understand different processing needs and provide customized formulas, technical support and after-sales service to help companies improve production efficiency and product quality.